In the context of the fast-paced era, women are increasingly pursuing clothing styles that reflect both individuality and taste. In this trend, "monocular mesh" is quietly becoming popular in the studios and show stages of major women's clothing brands with its unique structural design and delicate texture.

Perspective Fashion Frontier | Deciphering Why Monocular Mesh Sweeps Women's Show

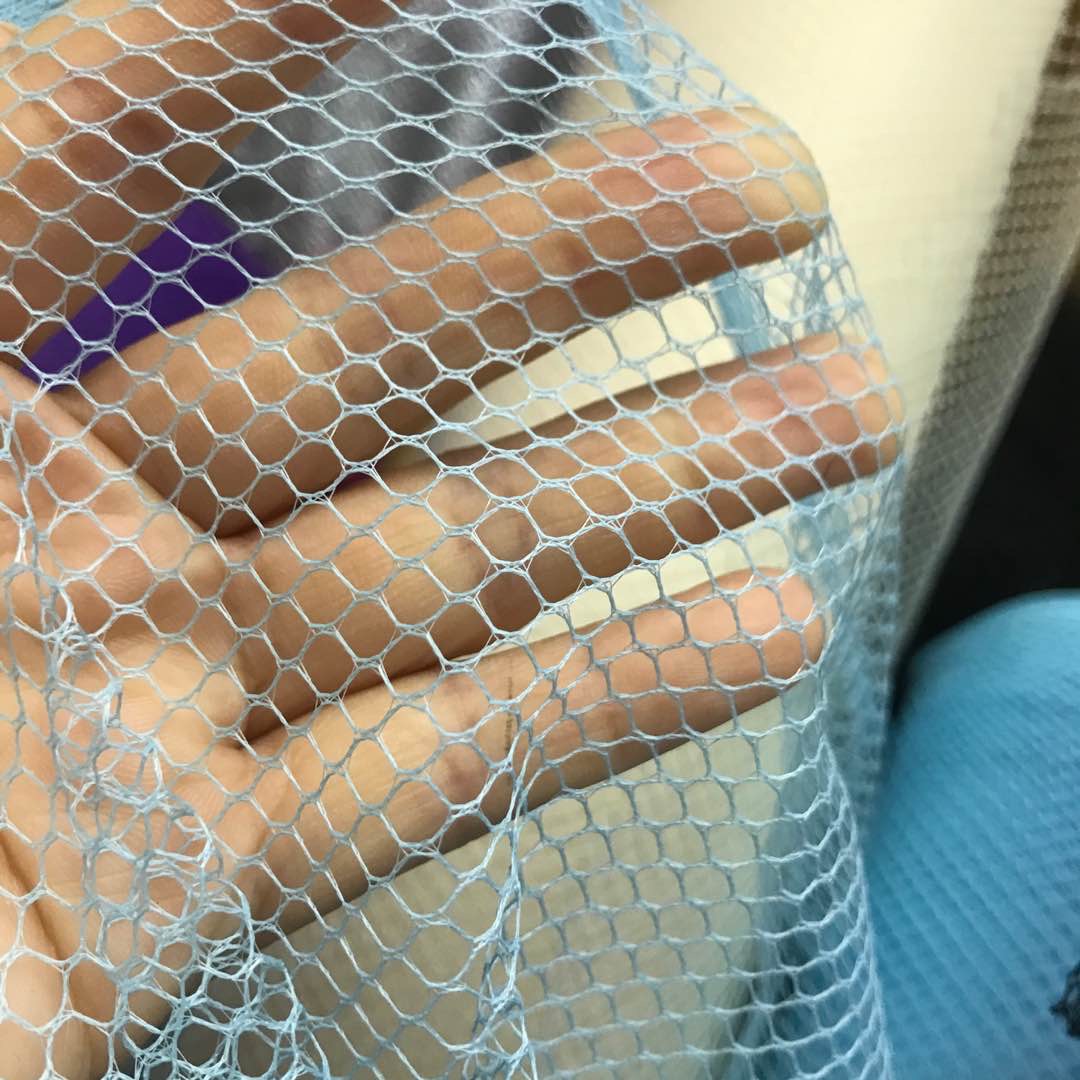

This unique mesh material, derived from the fine weaving process, stands out with its regularly distributed pore texture. Each small round hole is not only a beautiful bright spot, but also carries functional value-excellent ventilation makes it one of the irreplaceable core materials for spring and summer clothes.

At the same time, with the increasing demand of consumers for wearing experience, the concept of "light as air" has gradually taken root in the hearts of the people. When the traditional heavy cloth is difficult to meet the aesthetic demands of the new generation, this new type of mesh cloth with the advantage of breathing just fills the gap and brings an unprecedented refreshing feeling.

Where raw materials and aesthetics blend | Polyester technology gives clothing more possibilities

In addition to the eye-catching appearance, the products woven from high-density polyester yarn also show strong functional attributes. It is not only wear-resistant and tear-resistant, but also has excellent elasticity and color stability, and can withstand multiple washes and still shine as before.

the finished mesh fabric, which is supported by advanced coating and surface finishing technology, has a smooth and silky hand feeling, showing a slightly shining but not dazzling luster, making the whole garment more three-dimensional and advanced atmosphere, and touching people's hearts at the same time in vision and touch.

flexible supply chain power show | in stock supply combined with personalized customized win-win model to explore

Faced with the ever-changing market demand speed and diversified order types, this series of products innovates and launches a dual-track operation mechanism of "in stock inventory rapid response customization. Customers can not only obtain standardized specifications of fabrics for production start-up projects, but also propose exclusive pattern, weight or organization parameters for one-to-one development services.

especially for small and medium-sized designer brands or handicrafts, the low starting quantity and short delivery period greatly reduce the trial and error cost of new products. Even a small number of experimental purchases also enjoy professional quality control process guarantee.

case library of multiple application scenarios | see how designers from all walks of life play with this magical fabric

from the flowing and smart halter skirt on the runway to the street style stitching jacket, this universal item has already penetrated into many design contexts. Especially in the summer dress series, hollow patterns are cleverly used to create a looming effect, both sexy and elegant.

in addition, when the mix-and-match trend prevails, many avant-garde creators try to match it with tough textures such as leather, Denim and even suits to build rich outline lines to form a strong visual impact. In the field of accessories, some craftsmen have used the remaining leftover materials to make bags and earrings with a very futuristic tone, which is eye-catching.

portrait of the person responsible for green production | the concept of sustainable development runs through the whole process

As one of the responsible manufacturers, we always insist that environmental awareness is embedded in every process. At present, some of the raw materials used already contain recycled fiber components from the reprocessing of recycled PET bottles, and ensure that the quality of the final product is not affected.

in addition, it is worth mentioning that the full introduction of digital printing system has greatly reduced the total amount of water and electricity consumption and related chemical reagent emissions. according to the latest statistics, compared with the traditional dyeing and finishing methods, the water saving is more than 40%, thus truly saving energy and reducing consumption.