Discover how single eye mesh fabric is revolutionizing women’s fashion in 2024 and learn how to source premium quality polyester mesh fabric at wholesale prices.

Why Women's Fashion Brands Are Falling for Single Eye Mesh Fabric

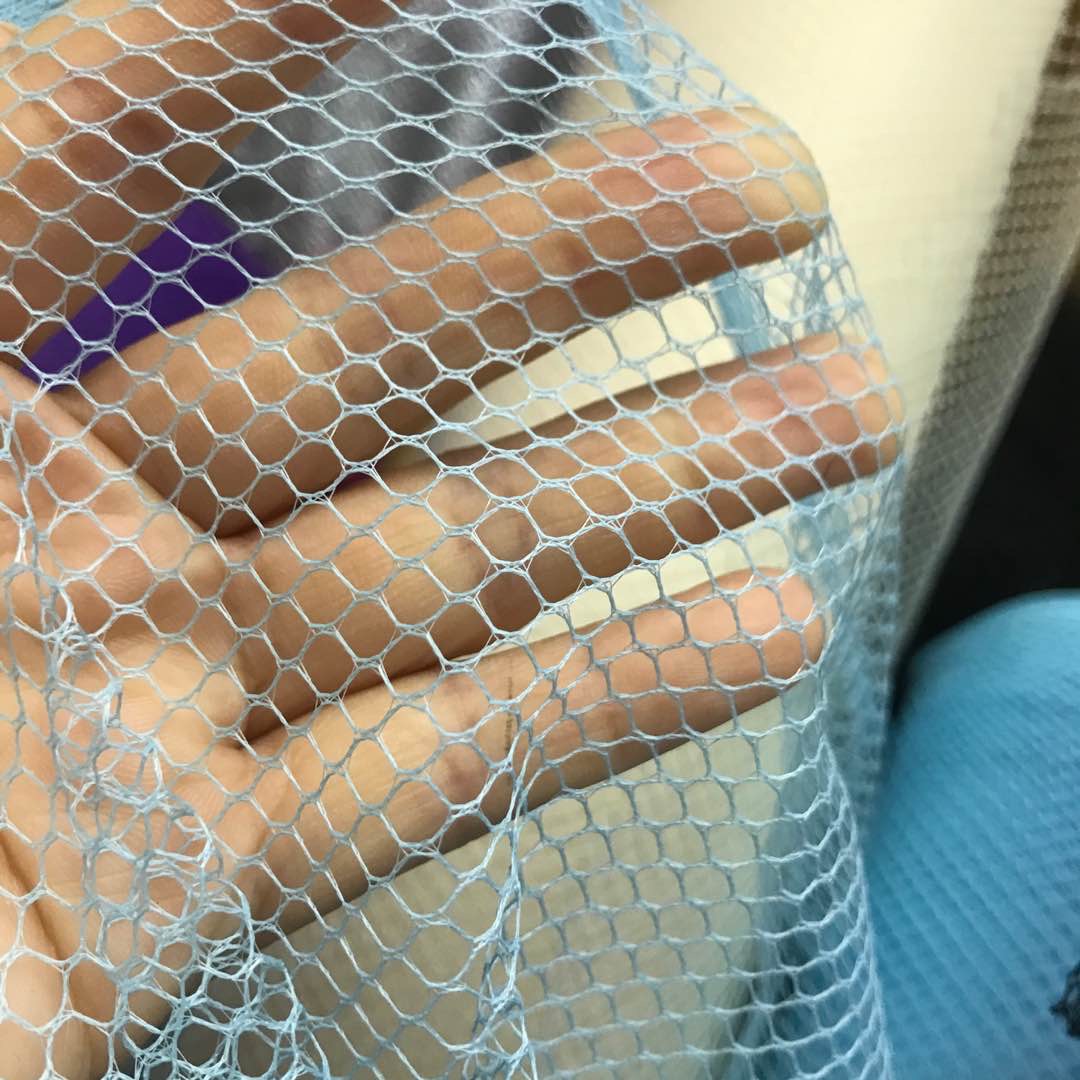

In 2024, the fashion world has embraced transparency — quite literally. Single eye mesh fabric is making waves across both luxury and fast fashion lines, offering a perfect balance of elegance and edge. From sheer dresses to breathable jackets, this versatile textile allows designers to play with layering, texture, and light in ways that captivate modern consumers. Whether it's a minimalist streetwear look or a dramatic runway ensemble, the adaptability of single eye mesh makes it a go-to fabric for designers aiming to stand out in a crowded market.

Understanding the Structure and Benefits of Single Eye Mesh

While the difference between single eye and double eye mesh may seem subtle, the impact on drape, breathability, and visual texture is significant. Single eye mesh features a distinct open-weave structure that allows for superior airflow without compromising on style. Compared to its double eye counterpart, it offers a lighter feel and a more refined aesthetic — ideal for warm-weather collections.

Made from high-quality polyester fibers, single eye mesh combines durability with comfort. Its inherent resistance to wrinkles and shrinking makes it a practical choice for both casual and formal wear. Additionally, polyester's adaptability to various dyeing and finishing techniques ensures that brands can achieve vibrant colors and unique textures. As sustainability becomes a growing concern, many manufacturers are now offering recycled polyester options, allowing brands to maintain their eco-conscious values without sacrificing quality.

Designing Your Own Custom Mesh Fabric: From Color to Texture

Customization is the heart of modern fashion, and single eye mesh offers endless possibilities. Designers can choose from Pantone-matched colors to ensure brand consistency across collections. When working with large quantities, it’s essential to test color fastness and consider how lighting and fabric finish will affect the final hue.

Texture can be enhanced through techniques like jacquard weaving, embroidery, or digital printing. Whether you're aiming for a subtle tonal pattern or a bold statement piece, the right finishing can elevate your design from ordinary to extraordinary. When placing custom orders, always specify the desired weight (measured in grams per square meter), width, and roll length to ensure the fabric meets your production needs.

Choosing the Right Manufacturer for Your Mesh Fabric Needs

When sourcing wholesale polyester mesh fabric, selecting the right supplier can make or break your production timeline and quality standards. Look for manufacturers with a proven track record in textile innovation, transparent production processes, and certifications like OEKO-TEX or REACH compliance. Countries like China, Turkey, and India are known for their robust textile industries, each offering different advantages in terms of cost, quality, and lead times.

Before committing to a large order, request a comprehensive sample kit that includes swatches of different weights, weaves, and colors. Pay attention to consistency in dyeing, edge finishing, and overall fabric integrity. A reliable supplier should also provide detailed technical data sheets and be willing to discuss customization options in depth.

Styling Inspiration: The Fashion Possibilities of Mesh Fabric

Mesh fabric isn’t just for runway shows — it’s increasingly finding its way into everyday fashion. Streetwear enthusiasts are layering mesh hoodies over graphic tees for a bold, urban look. In high fashion, designers are using it to create ethereal gowns with intricate lace-like detailing. Even in bridal fashion, mesh is being used to craft lightweight veils and semi-transparent overlays that add drama without weight.

For a more wearable approach, try a mesh overlay top paired with a simple camisole and tailored trousers. The contrast between sheer and solid textures adds depth and sophistication to any outfit. Whether you're designing for a niche market or a mass audience, mesh fabric offers a canvas that's both functional and expressive.

Cost-Saving Tips for Bulk Mesh Fabric Orders

Ordering in bulk can significantly reduce per-yard costs, but smart sourcing goes beyond just quantity. Negotiating MOQs (Minimum Order Quantities) with suppliers can open up more flexibility, especially for smaller brands. Choosing the right shipping method — whether by sea, air, or express courier — also plays a key role in managing costs without compromising delivery timelines.

Building a long-term relationship with a trusted supplier can unlock exclusive pricing, early access to new fabric collections, and dedicated support for custom projects. Always consider signing a formal agreement that outlines quality standards, payment terms, and dispute resolution procedures to protect both parties.

The Future of Mesh Fabric in Sustainable Fashion

As environmental concerns shape consumer behavior, the textile industry is evolving to meet new demands. Recycled polyester mesh is gaining traction, offering the same performance benefits as virgin polyester while reducing plastic waste. Innovations in eco-friendly dyeing and finishing techniques are also helping brands reduce their water and carbon footprint.

Consumers are increasingly drawn to brands that prioritize sustainability. By incorporating green textiles like biodegradable mesh or low-impact dyes into your collections, you can strengthen customer loyalty and differentiate yourself in a competitive market. The future of mesh fabric lies not just in aesthetics, but in responsibility and innovation.

Avoiding Common Mistakes in Working with Mesh Fabric

For new designers, mesh can present unique challenges in cutting and sewing. Its lightweight, slippery texture requires careful handling to prevent shifting during production. Using a walking foot or Teflon-coated presser foot can help maintain even feed through the sewing machine.

To avoid shrinkage or stretching, always pre-wash and dry the fabric before cutting. Conducting a wash test, stretch test, and colorfastness test before full production can save time and materials in the long run. Understanding how mesh behaves during different stages of garment construction is key to achieving professional results.